|

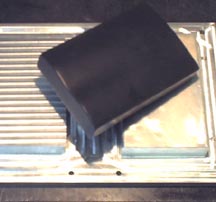

An aluminum mold for manufacturing an RTM carbon fiber part for the consumer electronics aftermarket.

An aluminum mold for injection molding a nylon part for aerospace applications.

| The Moldmaking Process, Expedited with Rapid Prototyping Services.The steps to producing a completed mold for injection molding are very complex and demanding. First a Mastercam drawing is done of what the finished part will look like. Then the drawing of the part is used to produce a drawing of the mold needed to produce the part. The two halves of the mold are cut on a HAAS CNC machine for tight tolerances and good finish. The knockouts for ejecting the parts from the injection molding machines are installed. The mold surfaces are polished according to specifications. The mold is installed in our TMC, Milacron or Newberry machine and prototype parts are produced. Because all of these steps are performed in one shop, there are no delays due to manufacturing conflicts or setup changes. Your rapid prototype job is our #1 priority, we will put you in the injection molding machines first.

|

|

|  |

|

Prototype and Manufacturing Consulting

Outside consulting services can bring fresh ideas to a problem project. Odyssey has specialized in solving "headache" prototyping problems for many clients. Our experience in complex moldmaking has brought us great opportunities to solve problems that other moldmakers couldn't. Often times the parts and molds were completely rethought, producing a part that will perform the same, looks almost identical, but is a more easily manufactured part.

|

An SLA prototpye for customer acceptance and ergonomics tests displayed on the finished mold used to manufacture a composite part using the Resin Transfer Molding (RTM) process.

|

|

|